Thermal Desorption Analyzer ESCO-TDS1200Ⅱ IR

Thermal Desorption Analyzer ESCO-TDS1200Ⅱ IR

Thermal Desorption Analyzer ESCO-TDS1200Ⅱ IR Features

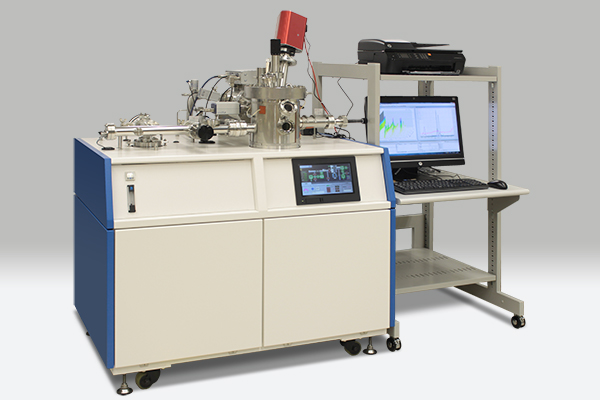

The Thermal Desorption Spectrometer ESCO-TDS1200Ⅱ IR is an analytical instrument that uses a quadrupole mass spectrometer (QMS) to observe in real time the molecules desorbed when a sample is heated by infrared radiation under a programed temperature ramp in an ultra-high vacuum environment (10⁻⁷ Pa or less).

Compared to thermal analysis instruments that heat samples at atmospheric pressure (10⁵ Pa), it enables observation in a low-background environment. It achieves high-sensitivity detection even for atmospheric components (water, hydrogen, oxygen, nitrogen, carbon dioxide, etc.) where low background levels are difficult to achieve at atmospheric pressure.

Furthermore, its design ensures only the sample is heated, preventing background noise from increasing even at high temperatures and enabling highly sensitive observation of desorbed molecules.

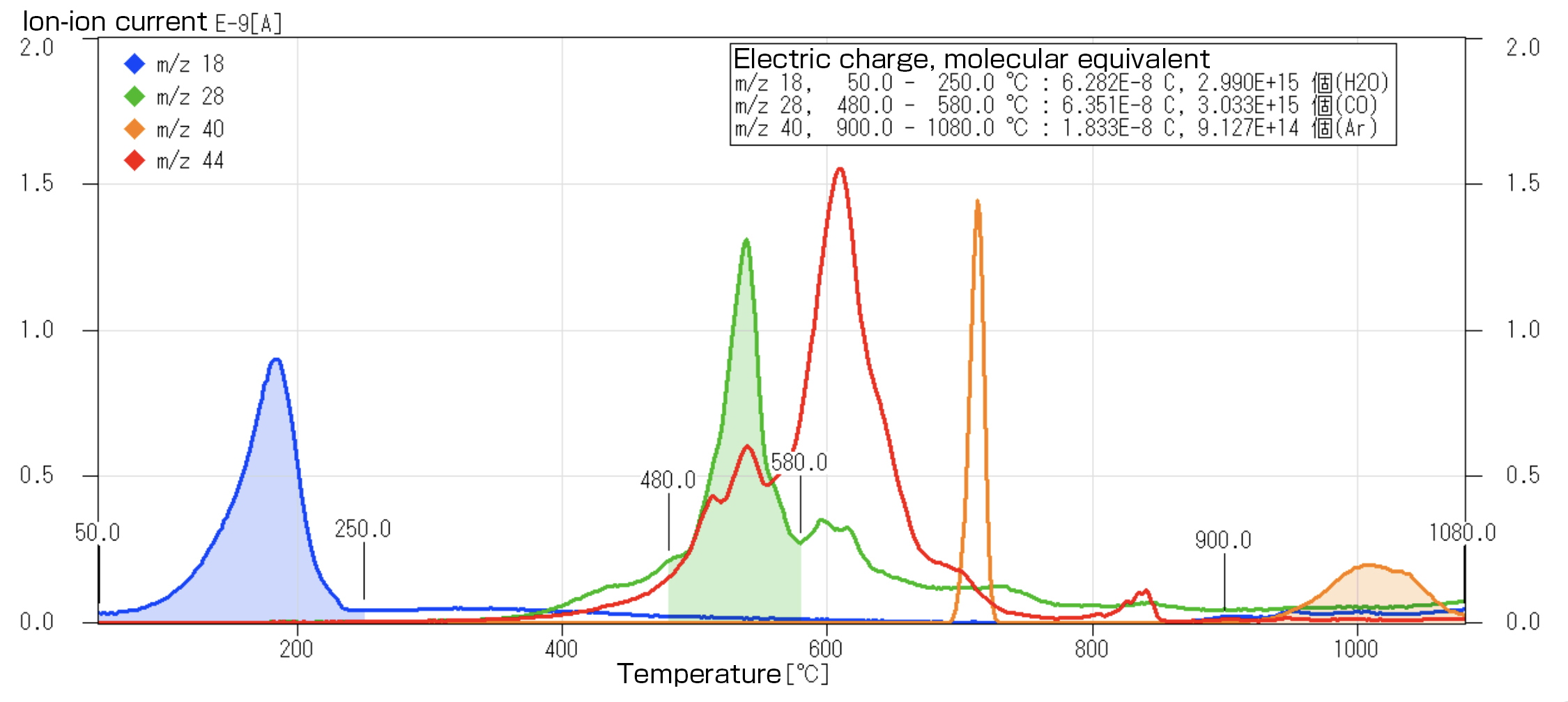

It enables the identification and quantification of chemical species for molecules desorbed from the sample. Information on the adsorption/binding state and diffusion process of desorbed molecules can also be obtained.

It is ideal for measuring thin film samples and thin plate samples. The new ESCO-TDS1200Ⅱ IR is a renewal of the conventional ESCO-TDS1200Ⅱ IR system, featuring a touch panel interface. It complies with CE Mark usage standards.

【References】

●Edited by the Japan Society for Vacuum Science and Technology; Illustrated Handbook of Surface Analysis. Asakura Shoten, 2021, Chapter V: Other Methods. Section 25: Desorption Analysis Methods. Item 1: Pyrodesorption Method (Masahira Ogura): 464-469.

●Norio Hirasita; Tsuneo Ajioka; Yasushi Hinaga. Development of a New Thermal Desorption Gas Analysis Instrument and Its Application to VLSI Material and Process Evaluation. Vacuum, 1991, 34.11: 813-819.

●Norio Hirakage; Taizo Uchiyama. Quantitative Analysis of Gases Released from Semiconductor Integrated Circuit Materials Using Thermal Desorption Gas Analysis. Analytical Chemistry, 1994, 43.10: 757-764.

Load Lock Chamber Equipment

Load Lock Chamber EquipmentLoad Lock Chamber Equipment

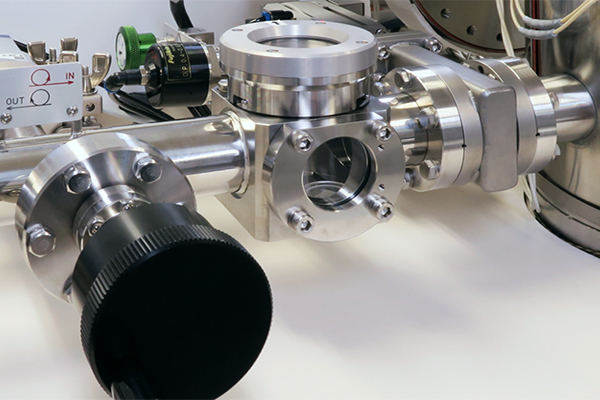

Load lock chambers are essential for achieving high measurement efficiency (high throughput) and high sensitivity. Our load lock chamber and sample transfer mechanism enable the rapid introduction of only the sample into the ultra-high vacuum analysis chamber.

Without a load lock chamber, the analysis chamber must be vented to atmosphere each time a sample is changed. Once vented, a large amount of atmospheric components (especially moisture) adsorb into the analysis chamber, requiring a long time for sufficient evacuation.

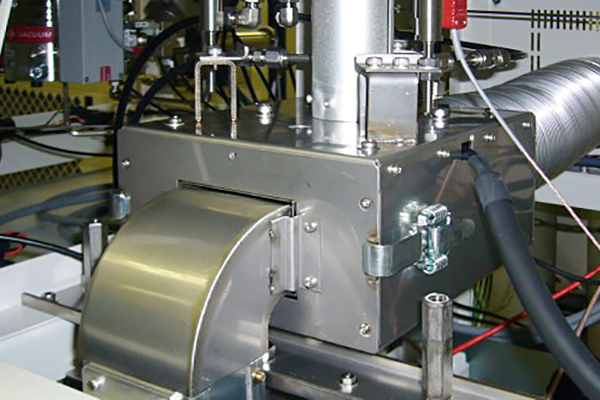

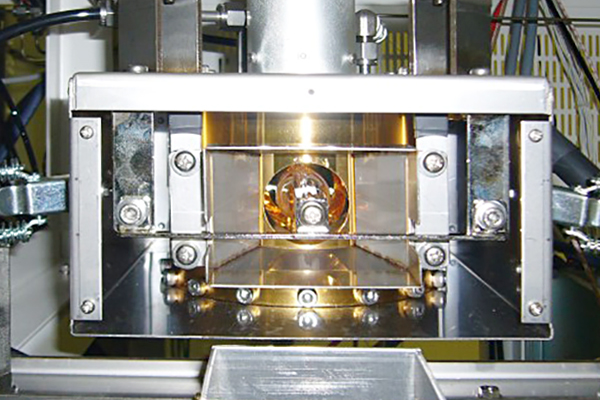

Infrared Heating System Image

Infrared Heating System ImageInfrared heating method

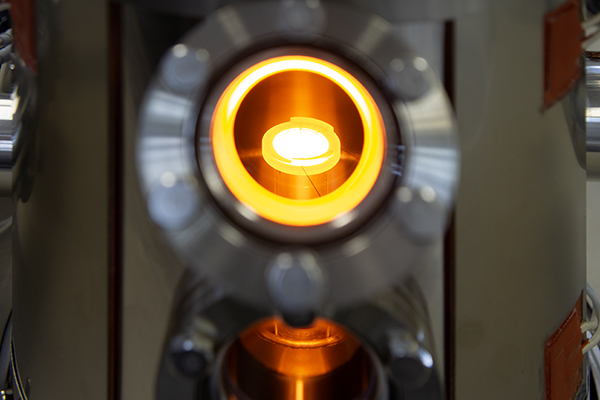

In thermal desorption analysis, it is crucial that the analysis chamber and its internal components remain unheated during sample heating. In TDS systems with chambers that are heated, it becomes difficult to distinguish between desorption gases from the sample and those from the chamber.

The ESCO-TDS1200Ⅱ IR directly heats the sample using infrared radiation introduced via a quartz rod. This minimizes background level increases even in high-temperature regions, enabling highly sensitive measurements.

Quadrupole Mass Spectrometer

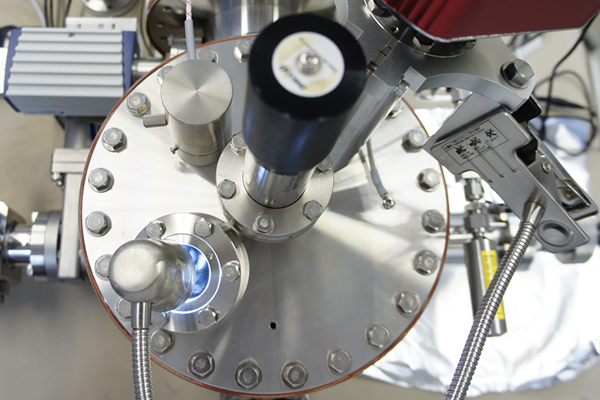

Quadrupole Mass SpectrometerQuadrupole Mass Spectrometer (QMS) Configuration

To detect desorbed gases with high sensitivity, the QMS ionization chamber is positioned directly above the sample. This direct placement allows gases desorbed from the sample to reach the QMS ionization chamber directly, enabling high-sensitivity detection even for highly volatile metals and large organic molecules.

Quantification of desorption gas

Data processing programs enable the quantification of desorbed gases. To quantify desorbed gases, the sensitivity of the mass spectrometer must be calibrated periodically.

Sensitivity calibration using standard leaks requires preparing an expensive standard leak for each gas type, making the calibration process time-consuming. Furthermore, using standard leaks for toxic gases necessitates strict safety and health management.

Our current quantification program enables faster, simpler, and safer quantification of desorption gases compared to the standard leak calibration method. Simply measure our NIST-traceable hydrogen standard sample periodically to obtain highly accurate results. Our developed sensitivity correction method can also correct sensitivity for gases other than hydrogen. It has been confirmed to closely match quantification results calibrated using standard leaks based on the national standard from the National Institute of Advanced Industrial Science and Technology (AIST).

【References】

●Norio Hirage; Mari Urano; Hajime Yoshida. Gas Release Measurement in Analytical Fields. Journal of the Vacuum Society of Japan, 2014, 57.6: 214-218.

Technical Explanation / Temperature-Programmed Desorption

Reference materials on desorption models and methods for determining activation energy used in analyzing thermal desorption analysis.

※The PDF file will open.

Technical Explanation / Quantitative Analysis (Quantitative Analysis in a Temperature-Programmed Desorption Analyzer)

This material is based on the report by Hirashita and Uchiyama in Analytical Chemistry, “N. Hirashita and T. Uchiyama, BUNSEKI KAGAKU, 43, 757 (1994).”

Quantification of desorbed gases can be performed from the temperature-programmed desorption (TPD) spectrum measured using a TPD analyzer.

When the exhaust rate of the measurement chamber is sufficiently large compared to the pressure change in the chamber caused by the desorbed gas, the change in partial pressure of the desorbed gas is proportional to the desorption rate (desorbed amount per unit time).

Since ion current and partial pressure are proportional in a mass spectrometer, the ion current ultimately becomes proportional to the desorption rate. Therefore, the total desorbed amount can be calculated from the area intensity obtained by integrating the ion current.

By determining the proportionality coefficient between area intensity and desorption amount using a Si sample injected with a known amount of H+, the hydrogen desorption amount can be determined for various samples based on the area intensity at m/z2.

Furthermore, for molecules other than hydrogen, the proportionality coefficient for the target molecule can be calculated using parameters such as the ionization difficulty, fragmentation factor, and transmission rate relative to hydrogen. Using this proportionality coefficient enables the quantification of molecules other than hydrogen.

Thermal Desorption Analyzer ESCO-TDS1200Ⅱ IR [Optional]

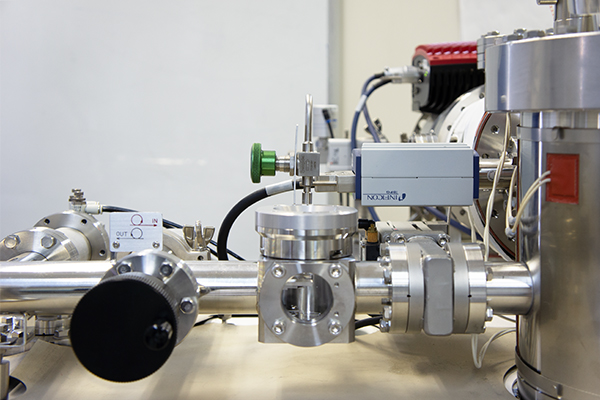

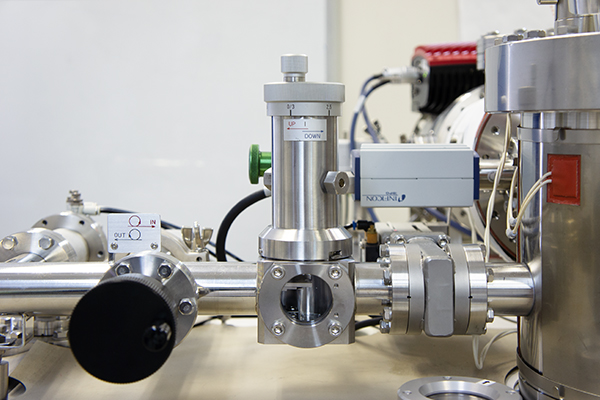

Switch-type valve assembly

Switch-type valve assemblyGas Purge for Powder Samples

This mechanism purges the load lock chamber without dispersing fine powder samples.

| 目的 | ・Purging the load lock chamber containing powder samples will cause the sample to scatter. ・A switch-type valve is used for the purge line. ・It enables easy operation and eliminates sample scattering. |

|---|---|

| Composition | Slow-Leak Valve Assembly (SUS Piping, Needle Valve, etc.) |

| Eligible for options | ・ESCO-TDS1200Ⅱ IR ・TDS1200 ・EMD-WA1000S/W ・EMD-WA1000S |

Transfer vessel

It enables the transfer of samples prepared in an anaerobic environment, such as a glove box, into the load lock chamber without exposing them to the atmosphere.

![]()

![]()

| Specifications | Air exchange rate = 1.5MPa → 1.5MPa (after 48 hours) |

|---|---|

| Composition | ・Transfer vessel (with pressure gauge optional) ・Load lock chamber for transfer vessel installation |

| Eligible for options | ・ESCO-TDS1200Ⅱ IR ・TDS1200 ・EMD-WA1000S/W ・EMD-WA1000S |

| Other | We also sell individual parts. When installing on a TDS, modification of the load lock is required. |

Sample Stage Exchange Mechanism

Sample stages can be exchanged without venting the main chamber to atmosphere.

Transparent stages and SiC stages can be easily swapped according to heating conditions.

Even if the sample stage becomes contaminated due to sample sublimation, it can be replaced immediately for peace of mind.

Cooling Water Circulation System

Cooling water circulation is required for cooling the infrared focusing mirror.

If the installation environment lacks a cooling water supply system, we recommend using a cooling water circulation unit in conjunction with it.

Options range from single-function cooling water circulation units to models equipped with various optional features.

When combined with a leak sensor, it can automatically shut off the cooling water circulation unit and infrared heating upon detecting a leak.

QMS Manifold

QMS ManifoldQMS Manifold

A space for installing the QMS analysis tube is provided between the main chamber and the turbo molecular pump.

This reduces metal deposition on the analysis tube, suppressing degradation of the QMS sensitivity.

Additionally, installing a liquid nitrogen trap enables more precise determination of hydrogen content in steel.

2kW heating source

Heating up to 1400°C is possible, compared to the standard maximum of 1200°C.

Consumables

Contact Us

If you have any questions or concerns about our products,

please feel free to contact us using the inquiry form below.