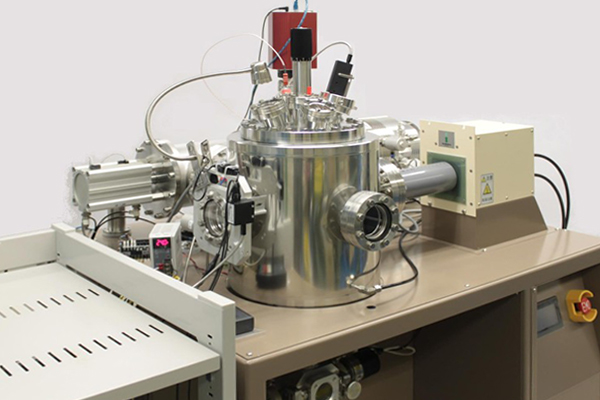

ESCO-TDS1700 IH High-Frequency Heating Thermal Desorption Analyzer

ESCO-TDS1700 IH High-Frequency Heating Thermal Desorption Analyzer

ESCO-TDS1700 IH High-Frequency Heating Thermal Desorption AnalyzerFeatures

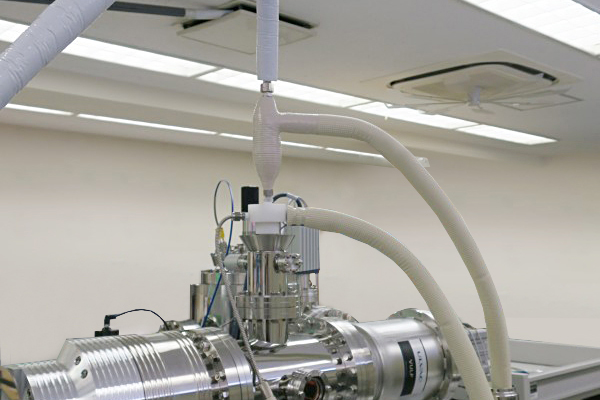

The ESCO-TDS1700 IH High-Frequency Heating Thermal Desorption Analyzer is an analytical instrument that uses a quadrupole mass spectrometer (QMS) to observe in real time the molecules desorbed when a sample is programmatically heated via electromagnetic induction heating under an ultra-high vacuum environment (10⁻⁷ Pa or less).

The ultra-high vacuum environment suppresses the effects of secondary reactions※1, enabling highly sensitive observation of desorbed components under ideal conditions.

It efficiently heats metallic materials such as steel, allowing measurements exceeding 1700°C.

It also enables low-temperature TDS measurements of diffusible hydrogen in steel, a factor contributing to hydrogen embrittlement (delayed fracture) in steel materials.

The main unit is automatically controlled by a PLC (Programmable Logic Controller) and features a touch panel interface.

※1 = Reactions occurring between heated samples and ambient components during measurement, or between components desorbed from samples and ambient components.

【References】

●Kitahara, G., et al. Evaluation of Corrosion Rate and Diffusible Hydrogen in Stress-Induced High-Strength Steel Plates under Corrosive Conditions. Materials and Environment, 2018, 67.4: 172-178.

●HANADA, Chihiro, et al. Suppression of bubble formation in levitated molten samples of Ti6Al4V with TiC for Hetero-3D at the

International Space Station (ISS). International Journal of Microgravity Science and Application, 2023, 40.3: 400301.

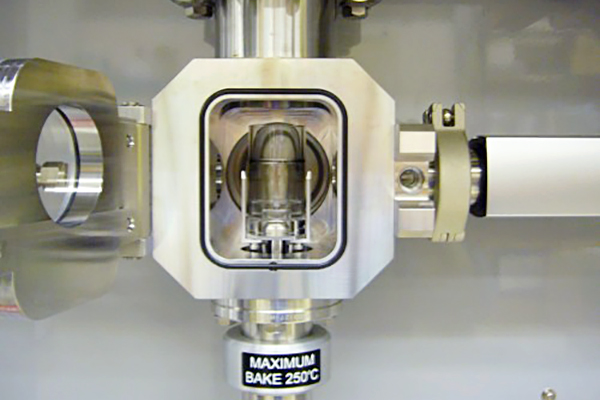

Load Lock Chamber Equipment

Load Lock Chamber EquipmentLoad Lock Chamber Equipment

Load lock chambers are essential for achieving high measurement efficiency (high throughput) and high sensitivity. Our load lock chamber and sample transfer mechanism enable the rapid introduction of only the sample into the ultra-high vacuum analysis chamber.

Without a load lock chamber, the analysis chamber must be vented to atmosphere each time a sample is changed. Once vented, a large amount of atmospheric components (especially moisture) adsorb into the analysis chamber, requiring a long time for sufficient evacuation.

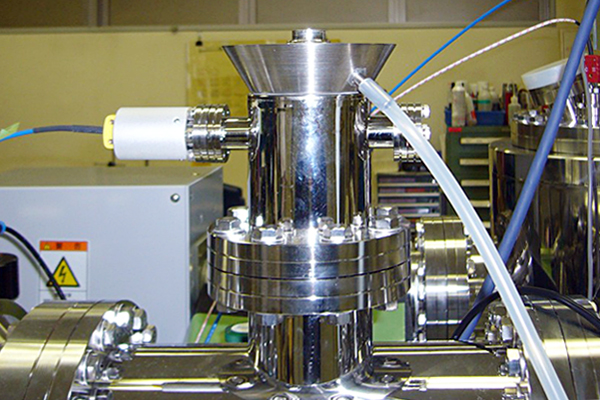

Cold Trap (Optional)

Cold Trap (Optional)Low-Temperature TDS Measurement of Diffusible Hydrogen in Steel

The ability to measure cooled steel specimens enables high-precision quantification of diffusible hydrogen in BCC steels with high hydrogen diffusion coefficients without allowing hydrogen to escape.

Frost forms on cooled steel specimens, and the desorption of this frost affects the hydrogen signal, becoming a source of error in the measured diffusible hydrogen amount (increasing uncertainty). The IH-TDS1700's cold trap (optional) minimizes this frost effect by trapping it, enabling the acquisition of a less distorted diffusible hydrogen desorption spectrum.

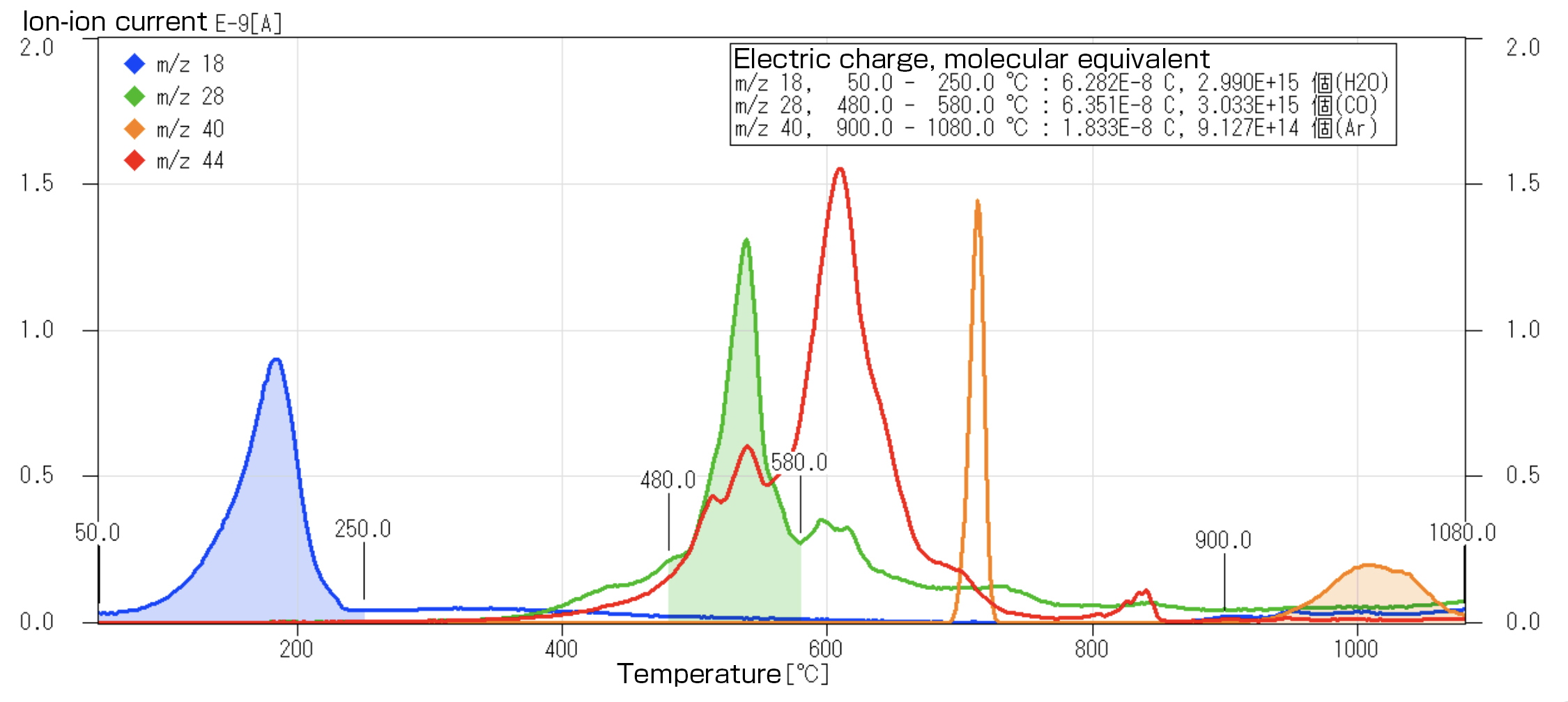

Quantification of desorption gas

Data processing programs enable quantification of desorbed gases. To quantify desorbed gases, the sensitivity of the mass spectrometer must be calibrated periodically.

Sensitivity calibration using standard leaks requires preparing an expensive standard leak for each gas type, making the calibration process time-consuming. Furthermore, using standard leaks for toxic gases necessitates strict safety and health management.

Our current quantification program enables faster, simpler, and safer quantification of desorption gases compared to the standard leak calibration method. Simply measure our NIST-traceable hydrogen standard sample periodically to obtain highly accurate results. Our developed sensitivity correction method can also correct sensitivity for gases other than hydrogen. It has been confirmed to closely match quantification results calibrated using standard leaks based on the national standard from the National Institute of Advanced Industrial Science and Technology (AIST).

【References】

●Norio Hirasita; Mari Urano; Hajime Yoshida. Gas Release Measurement in Analytical Fields. Journal of the Vacuum Society of Japan, 2014, 57.6: 214-218.

Technical Explanation / Temperature-Programmed Desorption

Reference materials on desorption models and methods for determining activation energy used in analyzing thermal desorption analysis.

※The PDF file will open.

Technical Explanation / Quantitative Analysis (Quantitative Analysis in Thermal Desorption Analysis Devices)

This material is based on the report by Hirashita and Uchiyama in Analytical Chemistry, “N. Hirashita and T. Uchiyama, BUNSEKI KAGAKU, 43, 757 (1994).”

Quantification of desorbed gases can be performed from the temperature-programmed desorption (TPD) spectrum measured using a TPD analyzer.

When the exhaust rate of the measurement chamber is sufficiently large compared to the pressure change in the chamber caused by the desorbed gas, the change in partial pressure of the desorbed gas is proportional to the desorption rate (desorbed amount per unit time).

In a mass spectrometer, the ion current is proportional to the partial pressure. Consequently, the ion current is proportional to the desorption rate, allowing the total desorbed amount to be calculated from the area intensity obtained by integrating the ion current.

By determining the proportionality coefficient between area intensity and desorption amount using a Si sample injected with a known amount of H+, the hydrogen desorption amount can be determined from the m/z2 area intensity for various samples.

Furthermore, for molecules other than hydrogen, the proportionality coefficient for the target molecule can be calculated from parameters such as the ionization difficulty, fragmentation factor, and transmission rate relative to hydrogen. Using this proportionality coefficient enables the quantification of molecules other than hydrogen.

High-Frequency Heating Thermal Desorption Analyzer

ESCO-TDS1700 IH [Optional]

Automatic Liquid Nitrogen Supply System

Automatic Liquid Nitrogen Supply System Radiation thermometer

Radiation thermometerSpecialized Option

Convenient liquid nitrogen automatic supply device and specialized radiometer options.

Consumables

| Standard sample | ⇒Hydrogen Ion Implantation Standard Sample |

||||

|---|---|---|---|---|---|

| F Remover | ⇒F Remover | ||||

| Heat-activated item | ⇒Alumina crucible | ⇒Tungsten ホルダー |

⇒Holder base | ⇒Quartz Tube A (Medium) | ⇒Quartz Tube A (Long) |

Contact Us

If you have any questions or concerns about our products,

please feel free to contact us using the inquiry form below.